Light Tower Repower Modules

The Perkins engine range provides unsurpassed reliability, performance and quality in even the harshest of environments. Perkins engines are supported in Australia by Allight through its extensive Perkins dealer network.

The Perkins 400 series diesel engine is ideal for use in construction, machinery, material handling, agricultural turf or general industrial equipment or electric power generation applications.The 400 series compact power has evolved to be a more powerful, reliable, compact, cleaner, quiet and cost effective engine choice for your equipment.

Advantages of the 400 series:

- High performance – excellent power and torque

- Low cost of ownership

- Engine reliability

- Compact package size

- EPA Tier 3/EU Stage 3 emissions compliant

- A wide range of options available

* Note: Perkins diesel engines are suitable for use on all models of Allight mobile lighting towers.

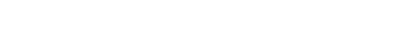

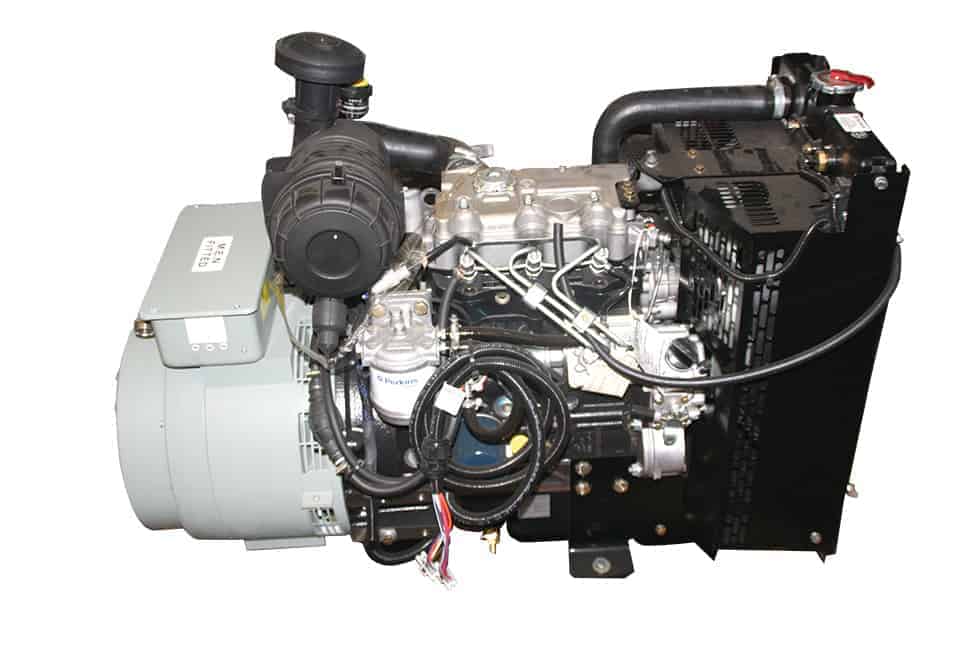

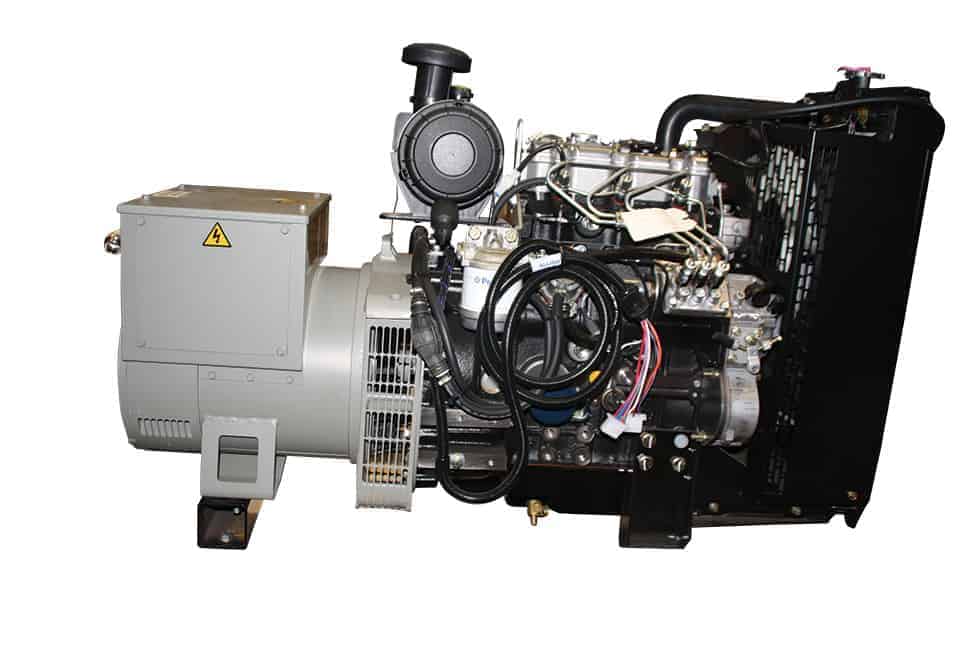

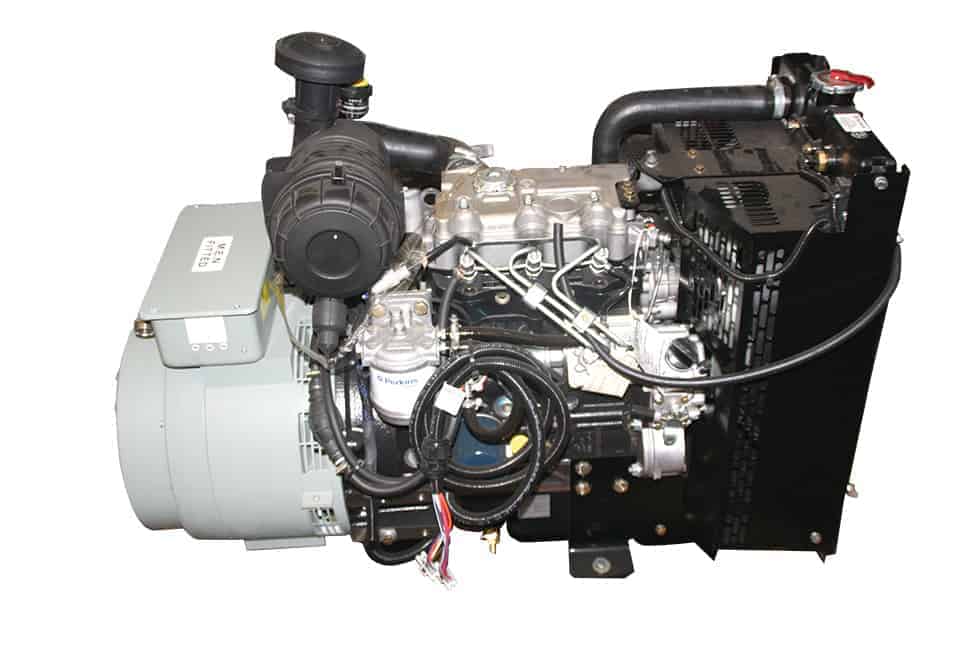

There are several Repower Modules available for your AIlightSykes mobile lighting tower, ranging from replacing only the engine through to complete engine, alternator and control panel modules.

Module One - LTM-3-00001

- Electra pack engine 403D-11 EP Tier 3 emission

- Allight Alternator TDWD-10 coupled to engine

- Horizontal muffler assembly

- Allight Skid base (engine & alternator coupled and assembled to skid)

- 4 x Anti vibration mounts for skid

- C1198 LED 3 DC control panel & wiring loom

- Engine and alternator fully bench tested

Module Two - LTM-3-00002

- Electra pack engine 403D-15 EP Tier 3 emission

- Leroy Somer, 50Hz alternator coupled to engine

- Horizontal muffler assembly

- Allight Skid base (engine & alternator coupled and assembled to skid)

- 4 x Anti vibration mounts for skid

- C1198 LED 3 DC control panel & wiring loom

- Engine and alternator fully bench tested

Module Three - LTM-3-00003

- Electra pack engine 404D-22 EP Tier 3 emission

- Leroy Somer, 50Hz alternator coupled to engine

- Horizontal muffler assembly

- Allight Skid base (engine & alternator coupled and assembled to skid)

- 4 x Anti vibration mounts for skid

- C1198 LED 3 DC control panel & wiring loom

- Engine and alternator fully bench tested

- Two stage air cleaner assembly (supplied loose)

Module Four - LTM-3-00004

- Electra pack engine 403D-11 EP Tier 3 emission

- Leroy Somer, 50Hz alternator coupled to engine

- Horizontal muffler assembly

- Allight Skid base (engine & alternator coupled and assembled to skid)

- 4 x Anti vibration mounts for skid

- C1198 LED 3 DC control panel & wiring loom

- Engine and alternator fully bench tested

Module Five - LTM-3-00005

- Electra pack engine 404D-22 EP Tier 3 emission

- Leroy Somer, 50Hz alternator coupled to engine

- Horizontal muffler assembly

- Allight Skid base (engine & alternator coupled and assembled to skid)

- 4 x Anti vibration mounts for skid

- C1198-LED 1-V2.1 start panel C/W 5 active LEDS

- Engine and alternator fully bench tested

- Two stage air cleaner assembly (supplied loose)

Module Six - LTM-3-00006

- Electra pack engine 403D-11 EP Tier 3 emission

- Allight Alternator TDWD-10 coupled to engine

- Horizontal muffler assembly

- Allight Skid base (engine & alternator coupled and assembled to skid)

- 4 x Anti vibration mounts for skid

- C1198 LED 3 DC control panel & wiring loom & Auto start & timer shut down

- Engine and alternator fully bench tested

WHY ALLIGHT?

TALK DIRECTLY WITH

THE ENGINEERING EXPERTS

If customisation requirements are what you are after, we have a team of in-house engineers and technical experts who can work with you to develop bespoke solutions for your requirements.

PREMIUM BUILD

SPECIFICATION

We provide Australian made, robust and reliable products for the most challenging and demanding applications. Our in-house engineering team can custom-design and manufacture bespoke equipment to match any specification supplied.

LOW OPERATION

AND MAINTENANCE COSTS

We believe in optimising efficiency and reducing downtime to make ownership safe, simple and cost-effective for you. We have refined our product range through design and manufacturing, and by servicing our own equipment, which operates in the harshest conditions. We are proud to manufacture quality products with reduced downtime and energy usage, keeping your operations and maintenance costs down.

BROAD AND FLEXIBLE EQUIPMENT RANGE

We offer an extensive range of mobile light towers, generators and engines to meet and exceed customer expectations in all market segments.

QUALITY CUSTOMER SERVICE AND AFTERMARKET

Our genuine parts and customer service teams are on hand to make sure you can access qualified, professional and highly skilled technicians when you need them most.

STOCK AND MANUFACTURING CAPABILITY

We understand quick turnaround is important to you. That’s why our Light Tower stock program provides you with fast access to equipment solutions.