Perkins engine company was founded in Peterborough, UK in 1932 by Frank Perkins and Charles Chapman. With very little money, but big ideas and vision, the 2 men set about revolutionising the motor industry by introducing one of the world’s first, small high-speed diesel engines. During the companies first year, 35 engines were produced, which was soon followed by rapid expansion into the industrial sector producing a total of 556 engines by the end of 1936.

By 1947 a new headquarters was established at the Eastfield factory in Peterborough UK. Six years later, with the focus on expansion, Simpson and Co. of India became the first of hundreds of licensees and distributors all over the world. Perkins was on the way to becoming the global company that it is today. By 1964 the iconic 4.236 engines was introduced. This went on to power more than 4.5 million machines worldwide with Perkins winning its first Queens award for business enterprise by 1966.Annual worldwide production topped 350,000 units by 1969, firmly establishing Perkins as a leader in its sector. By 1976 annual worldwide production reached 500,000 units for the first time. Leaping from strength to strength, Perkins celebrated the production of its 10,000,000 engine with Prima, the world’s first truly high speed direct injection engine in 1985.1999 saw the diesel engine industry faced with a future of tightening emissions legislation. Perkins launched its new 1000 Series range with more customer benefits and emission compliance. By 2007 Perkins global manufacturing facilities celebrated the company’s 75th anniversary whilst announcing plans to build a new facility in China. Spanning over 85 years of innovation, since the founding of the company in 1932, Perkins strives to use the best and most up-to-date technology to drive continual product improvements. Whilst Perkins is built on history and tradition, retaining the original focus on the development and manufacture of engines is key to Perkins today.

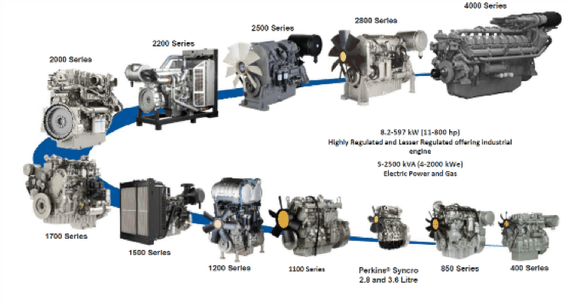

As one of the world’s leading suppliers of off-highway diesel and gas engines, Perkins offers a wide range of engines. The 400 series is available in in-line 2, 3 and 4-cylinder options in both turbocharged and naturally aspirated configuration. With power ranging up to 19Kw for industrial and 36KVA for electric power, Perkins offers a product to suit any application. The 4000 series supports multiple market segments comprising of manufacturing installations, real estate, telecom towers and hospitality. Covering both prime and standby power requirements, the 4000 series is available in In-line 6 and 8-cylinder configuration as well as 12 and 16-cylinder vee configuration. Designed to provide dependable, reliable and cost-effective power for continuous and emergency use, the range provides prime power from 6-2250 kW with standby power from 33-2500 kW. has been designed to provide instant response with thousands of hours of dependable running in harsh environments and strenuous conditions.

Allight is proud to be the official distributor for Perkins engines in Australia. As well as Perkins being our brand of choice to power our own light tower and other products, we’re also the only source of standalone engines in Australia. With a strong history with the Brand and a fully capable team on hand to assist you with your needs, you can count on us for service and support also.

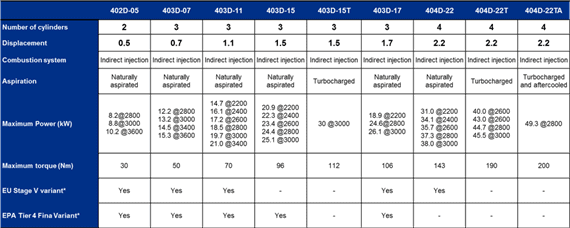

Our most popular engine, the 400 series, offers the following:

- 5 engine displacements: 0.5L, 0.7L, 1.1L and 1.7L, 2.2L

- Simple and proven technology – no after-treatment, no EGR

- Turbo and turbo aftercooled ratings available on some models for higher power density and better altitude capability

- Choice of curves. Different rated power, max torque, and rated speeds for matching to different machines

- Constant speed ratings also available e.g. for light towers

- Common solutions for many world emissions – saves OEMs time and money in machine development

- Machine electronic integration possible through E-governor solution compatible with all except 0.5L

Our engines build specifications offer a wide range of options with a displacement and power rating to suit almost any application. The 400-series specification range can be seen below:

Maintenance of your Perkins engine is paramount and for routine maintenance, a basic toolkit is all that is required. Oil and fuel filters are easy to change as the design of the 400 series offers simple, easy access with a choice of dipsticks and oil filer locations to best suit your application. Total operating cost or total cost of ownership (TCO) is kept lower due to long service intervals of 500 hours with a 1000-hour option on some products (e.g. 1.1L in light towers).

But whilst general maintenance may be carried out using basic tools, we also offer a range of properly designed and tested tools to carry out more in-depth service and maintenance procedures in the most correct, efficient and safe manner.

Our specialist tool catalogue offers everything from a crankshaft oil seal guide/protector, idler gear shaft installer and oil pump puller on our smaller engines, right the way through to an injector sleeve remover or cylinder liner replacement tool on our larger engines. Without these special tools a full and proper service of Perkins engines cannot be performed.

If you need more information, personal assistance or expert advice, we encourage you to contact our Perkins engine specialist.

Sources

1. https://www.perkins.com/en_GB/company/heritage/the-perkins-story.html

2. Perkins History Presentation –Perkins Engine Company 2014

3. EP Range Presentation December 2015 – Perkins Engine Company Ltd

4. Electric Power Sales Presentation – Perkins Engine Company Ltd 2015

5. 400 IDI Sales Pack – Perkins Engine Company Ltd 2015

6. Perkins Specialist Tool Catalogue 2018